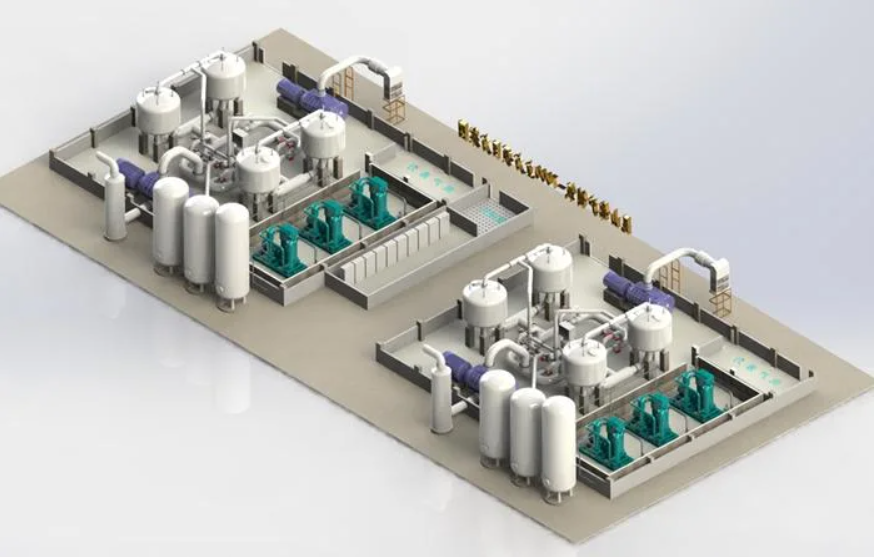

Nitrogen generator

Nitrogen system equipment is composed of air compressors, cold dryers

Filter, air storage tank, nitrogen generator composition.Pressure swing adsorption nitrogen production is based on clean, dry compressed air as raw material, and uses a high-efficiency and highly selective solid adsorbent (carbon molecular sieve) to selectively adsorb nitrogen and oxygen to reduce the nitrogen and oxygen in the air. separate from. Carbon molecular sieves are non-polar molecules and preferentially adsorb oxygen. The separation effect of carbon molecular sieve on oxygen and nitrogen is mainly based on the different diffusion rates of these two gases on the surface of carbon molecular sieve. Gas with a smaller diameter (oxygen) diffuses faster, and more enters the solid phase of the molecular sieve. Gas with a larger diameter ( Nitrogen) diffuses slowly and less enters the solid phase of molecular sieve. In this way, nitrogen-rich components can be obtained in the gas phase. After a period of time, the adsorption of oxygen by molecular sieve reaches equilibrium. According to the different characteristics of carbon molecular sieve for adsorbing gas under different pressures, the pressure is reduced to release carbon molecular sieve from adsorbing oxygen. This process is called regeneration. The pressure swing adsorption method usually uses two towers in parallel, alternately performing pressure adsorption and decompression regeneration, so as to obtain a continuous nitrogen stream.

Provide maximum commercial value

1. The filling and compaction of molecular sieve is done in a professional environment in a professional way.

The density is greater and the efficiency is higher.

2. The design of process and structure is optimized, and the system can exert its maximum potential.

·Higher reliability

1. Adopt a special valve that is frequently switched over 1 million times without failure to ensure the system's

Stable operation.

2. The system design is more reasonable, and the equipment is safer and more reliable.

More convenient to use

1. Nitrogen can be automatically recorded, which is convenient to find the working status at any working time.

2. The system runs fully automatically, and the whole process can be unattended.

parameters

Nitrogen gas production | 80Nm3/h. "Nm3/h" refers to the flow unit at 20℃, 0.101MPa(absolute pressure), and the flow meter is monitored online |

Nitrogen purity | ≥99% (non-oxygen content), 3-digit nitrogen analyzer online monitoring, digital display |

Oxygen content | ≦0.1%,≦10000ppm |

Nitrogen atmospheric pressure dew point | -20℃,126.8ppm,absolute humidity: 0.09491g/m3. Hongbo can provide dew point meter for inspection and acceptance |

Nitrogen pressure | 0.8 MPa(G),pressure gauge online monitoring, pointer display |

Dust content of nitrogen | ≤0.01ppm |

Nitrogen oil content | ≤0.001ppm |

Noise | 75 dB (1 meter away from the equipment, in an open environment, measured noise does not exceed 75 dB) |

Tel:0086 0531 61317512

Tel:0086 0531 61317512  Email:sales1@zhiweihuanbao.com

Email:sales1@zhiweihuanbao.com